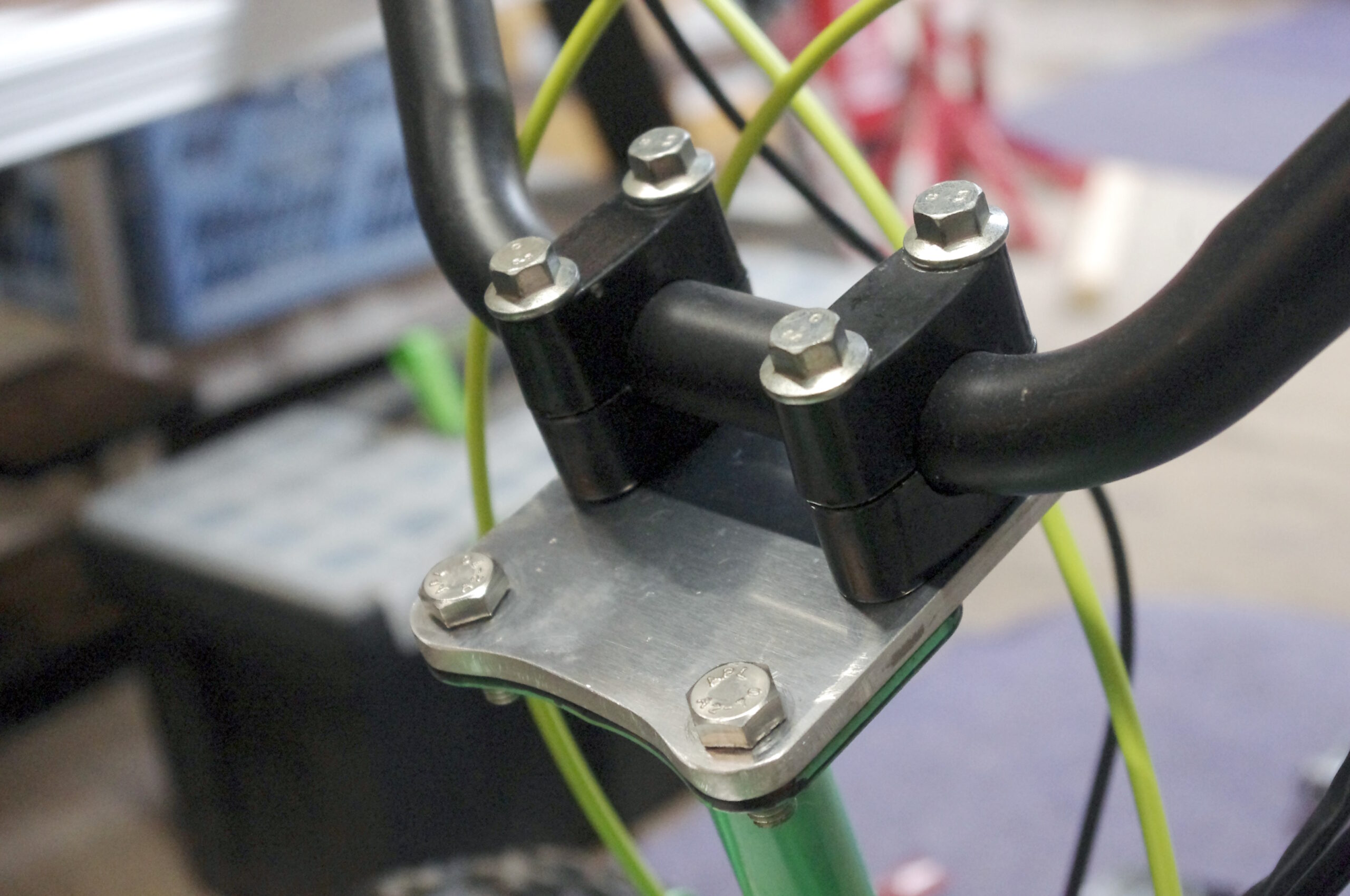

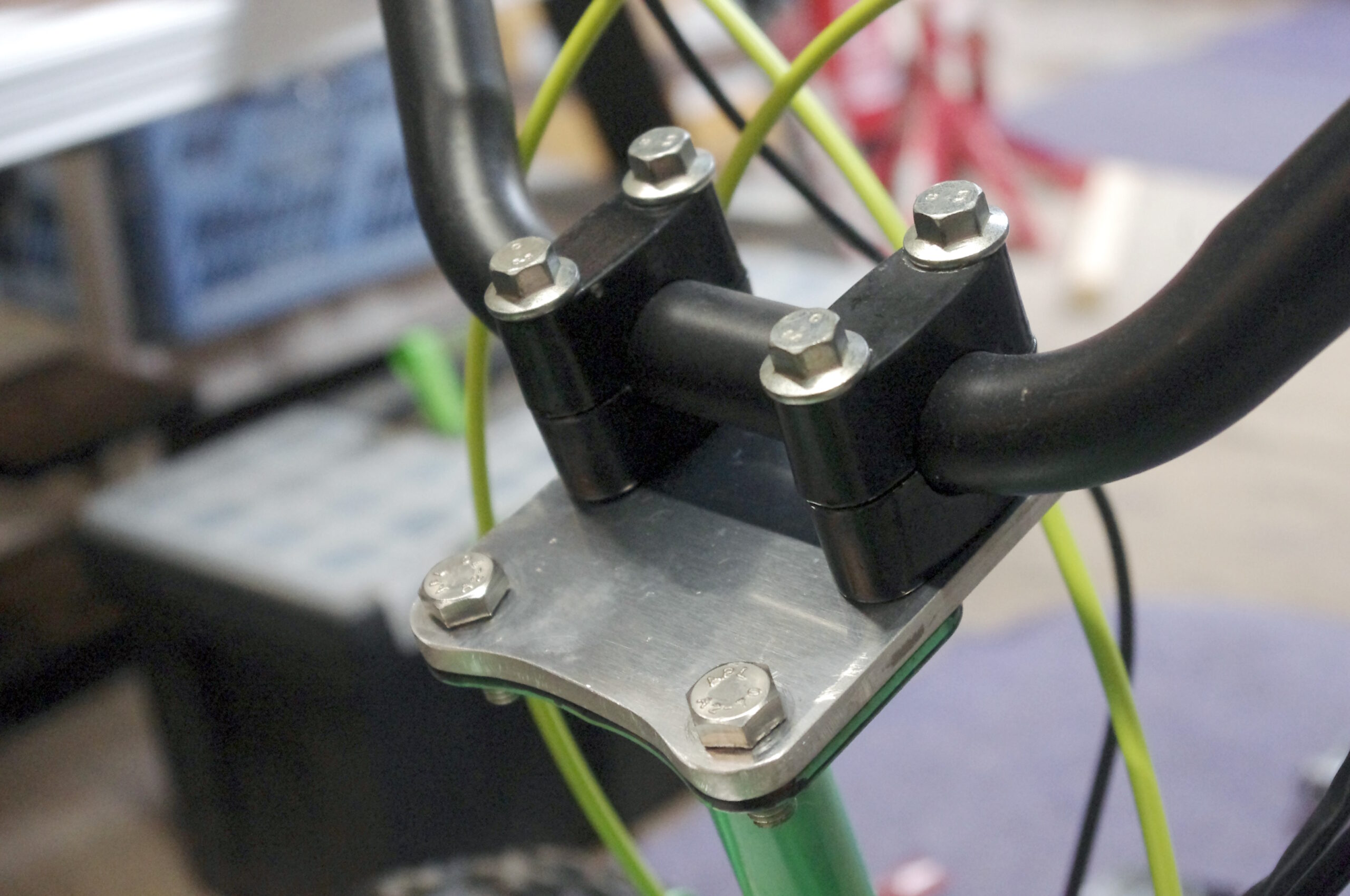

Electric Quad: Steering Bracket

After test riding the quad, it became obvious that this quad bike was made for children and I am an adult. One of the main […]

After test riding the quad, it became obvious that this quad bike was made for children and I am an adult. One of the main […]

After a fair amount of time in various states of disrepair, the quad has finally been reassembled and taken for a test ride. Check out […]

Iron (III) Oxide. Great for making thermite, crap for structural/mechanical systems. Thankfully there are rust removers available that will rid you of this troublesome oxide. […]

When it comes to removing paint from metal there are many options involving heat, chemicals and abrasives. As part of the quad project, I hope […]

Copyright © 2025 | WordPress Theme by MH Themes