In The Beginning

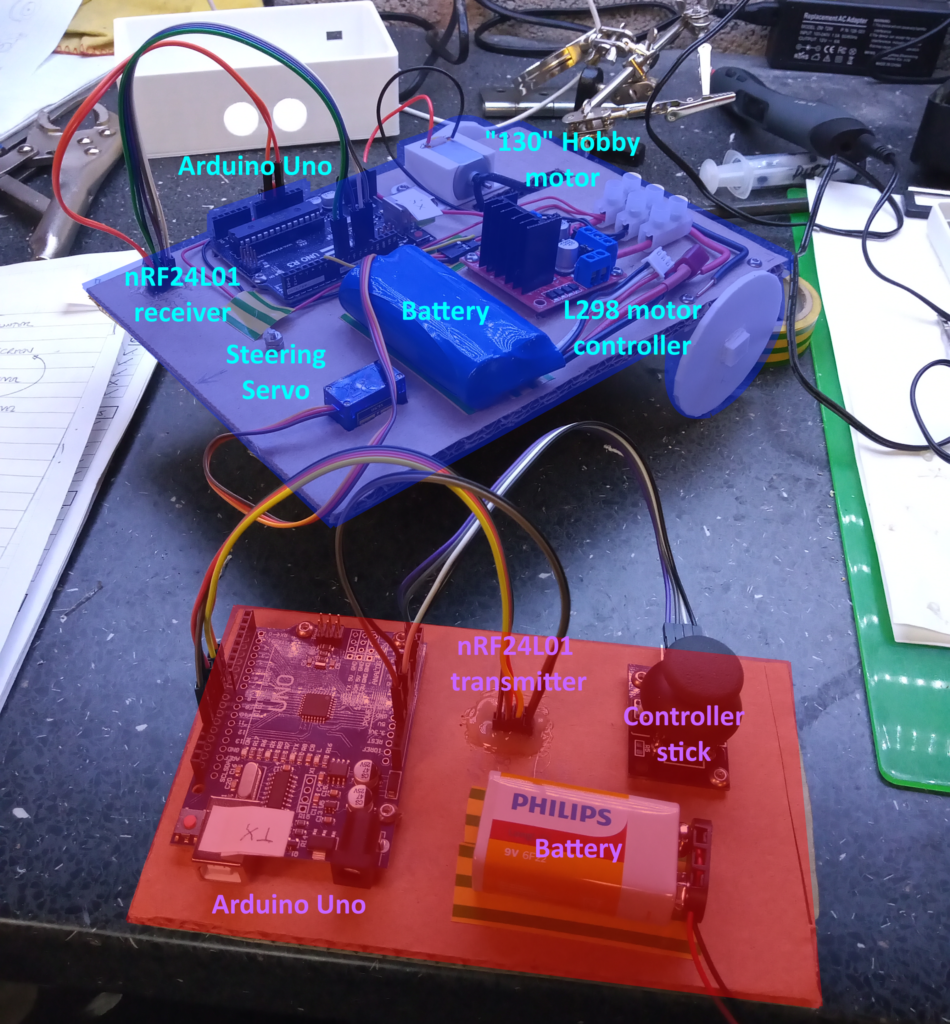

Every story has a beginning, and this build is no different! After conquering the various pitfalls of the nRF24L01 transceivers and successfully transmitting multiple data packets, it was only a matter of time until a remote-control vehicle was produced.

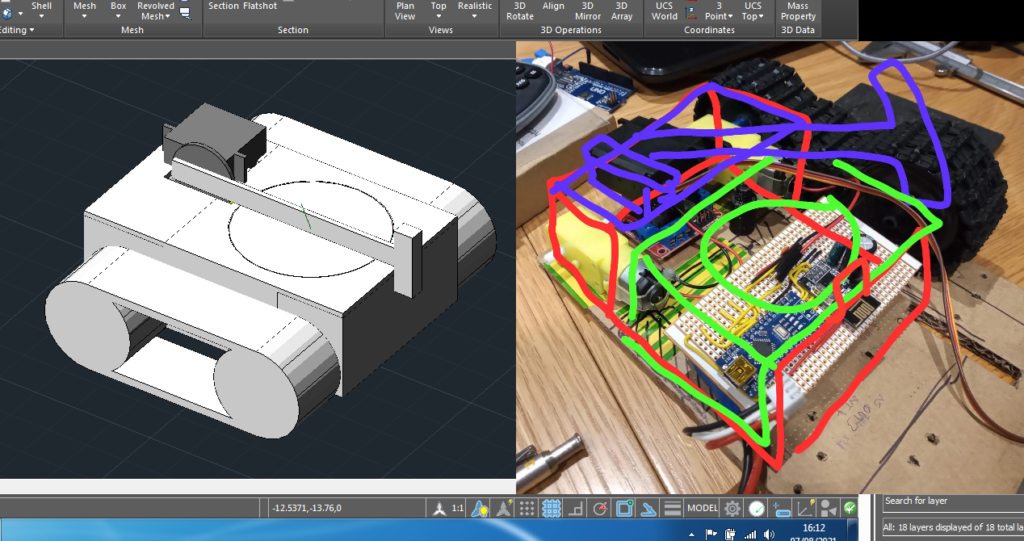

The first test rig was constructed using carboard, hot glue and a rudimentary 3D printed rear axle assembly. As with every first attempt at something new: the results were underwhelming at best, as evidenced below.

The controls were backwards, the steering didn’t work, both the radio transmission and power transmission were poor, BUT I was able to remotely ‘control’ a vehicle. Mission failed successfully.

Transformation to Battle Bot

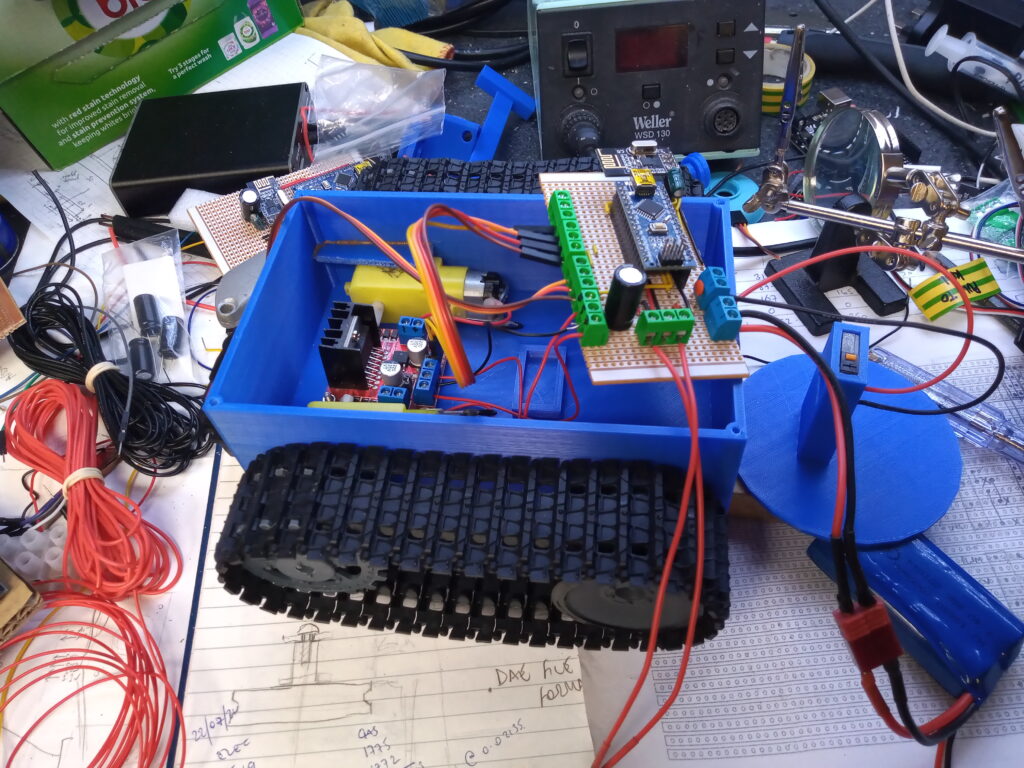

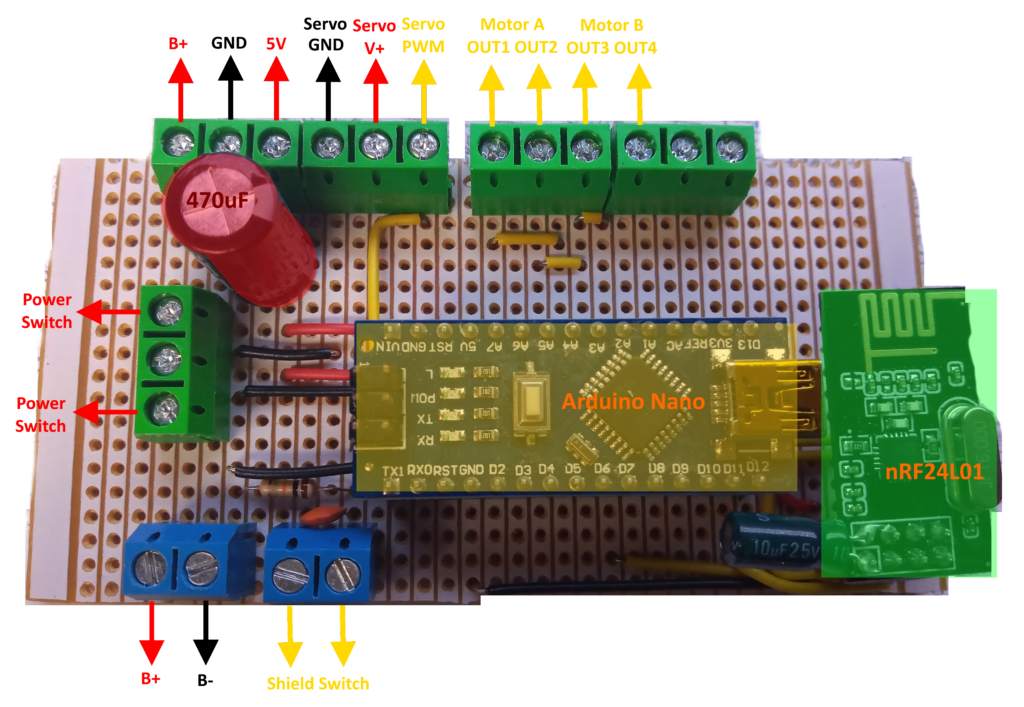

Two motors with integrated gearboxes were incorporated into the final design and the power was sent to a pair of caterpillar tracks giving it a responsive and agile feel.

Each bot is fitted with a ‘kill switch’ on the upper face of the 3D printed case and a hammer as a weapon.

Aim of the game is to hunt down, engage and hit your opponent’s kill switch with your hammer before they do the same to you. Almost like mechanised kiss chase.

With a standardised platform, the game becomes less about the capabilities of the bot and more about the driver’s skill.

The transceiver modules allow for up to 128 bots to compete together at the same time; chasing each other in the ultimate battle royale.

Future Plans

For the game to succeed as a multiplayer platform, there needs to be reliable cross channel communication between the bots.

Implementing this communication would require numerous hardware changes to both the electrical and mechanical elements. The electrical changes will need to be complemented with software updates.

The knock-on effect creates the need for user interfaces and communication protocols.

This is Tracy. And when Tracy turns up, I fuck off.

Past Lessons

They say that you learn from your mistakes; so here are some of the lessons I’ve had along the way.

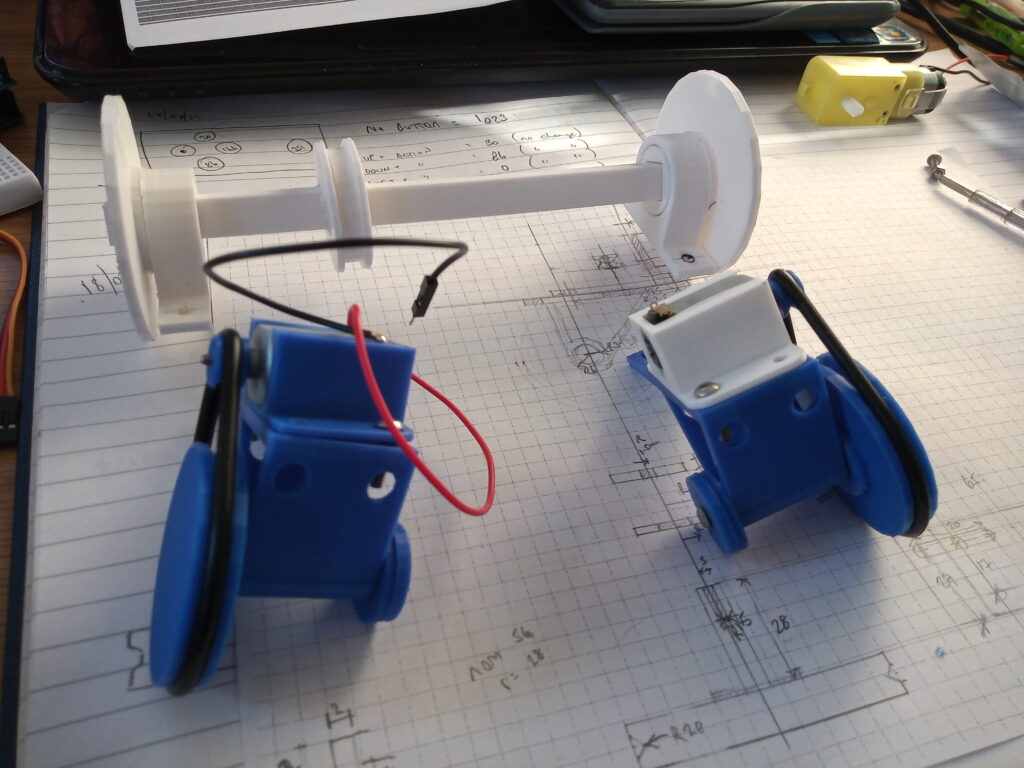

In the background is the original axle (white). This worked like dogshit – far too much friction. The foreground shows second version in blue – these were even worse!

3D printing allows for fast prototyping, however, it’s not so fast when you require five iterations.

The project gave me greater appreciation to mechanical design as well as providing experience with motor control and 2.4GHz radio transmissions. Many of the parts for this project have been donated to the Bark Blind project.

Last Updated: 13/11/2022