Sometimes the best way to learn a new thing is to use it in a new project.

This little project was a short and successful foray into the world of printing TPU flexible on a stock* Ender 3 Pro.

*This in reference to a Bowden type extruder. In the interests of openness and honesty the printer has been upgraded with a metal extruder, Capricorn tube & yellow bed springs.

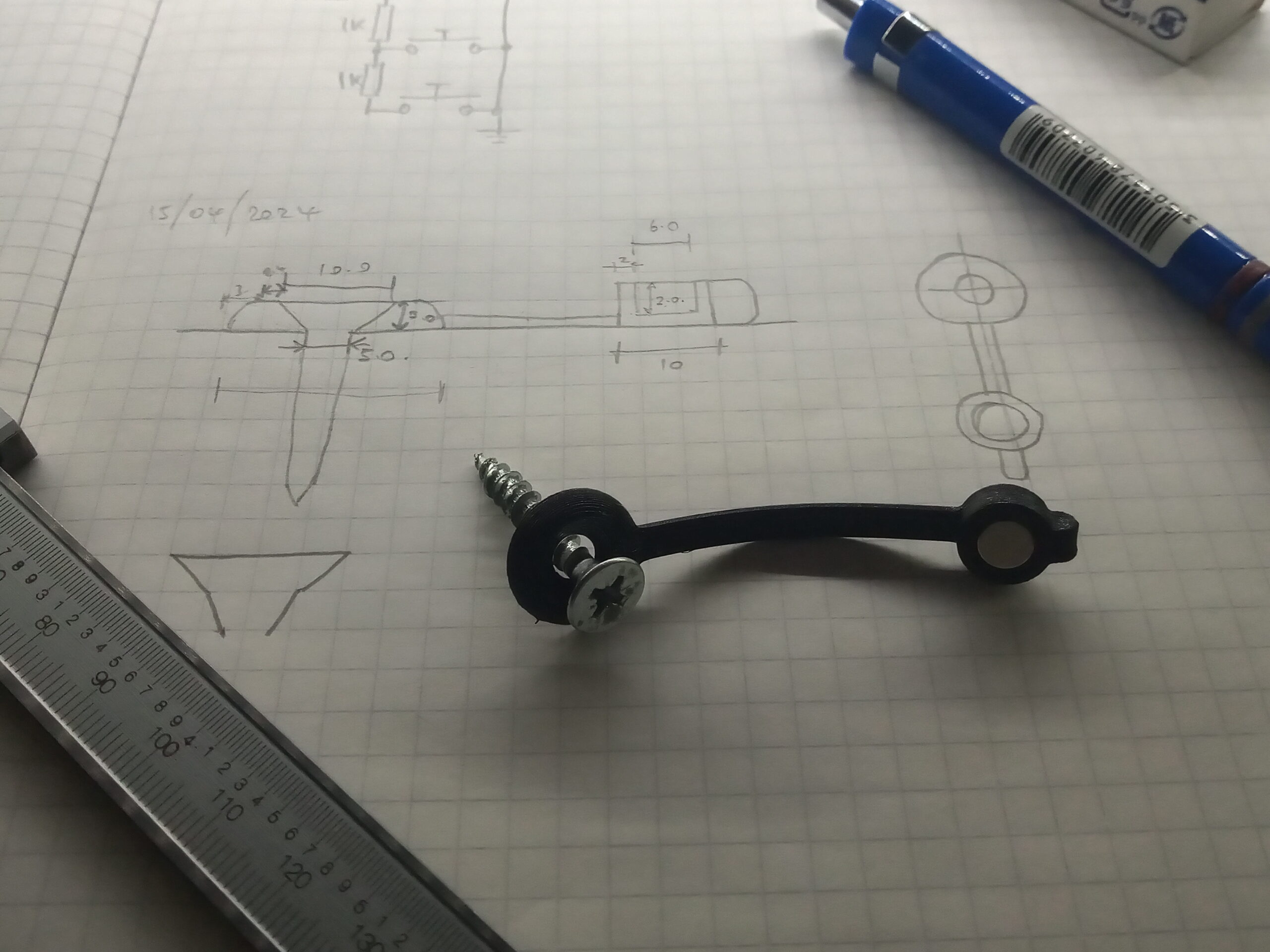

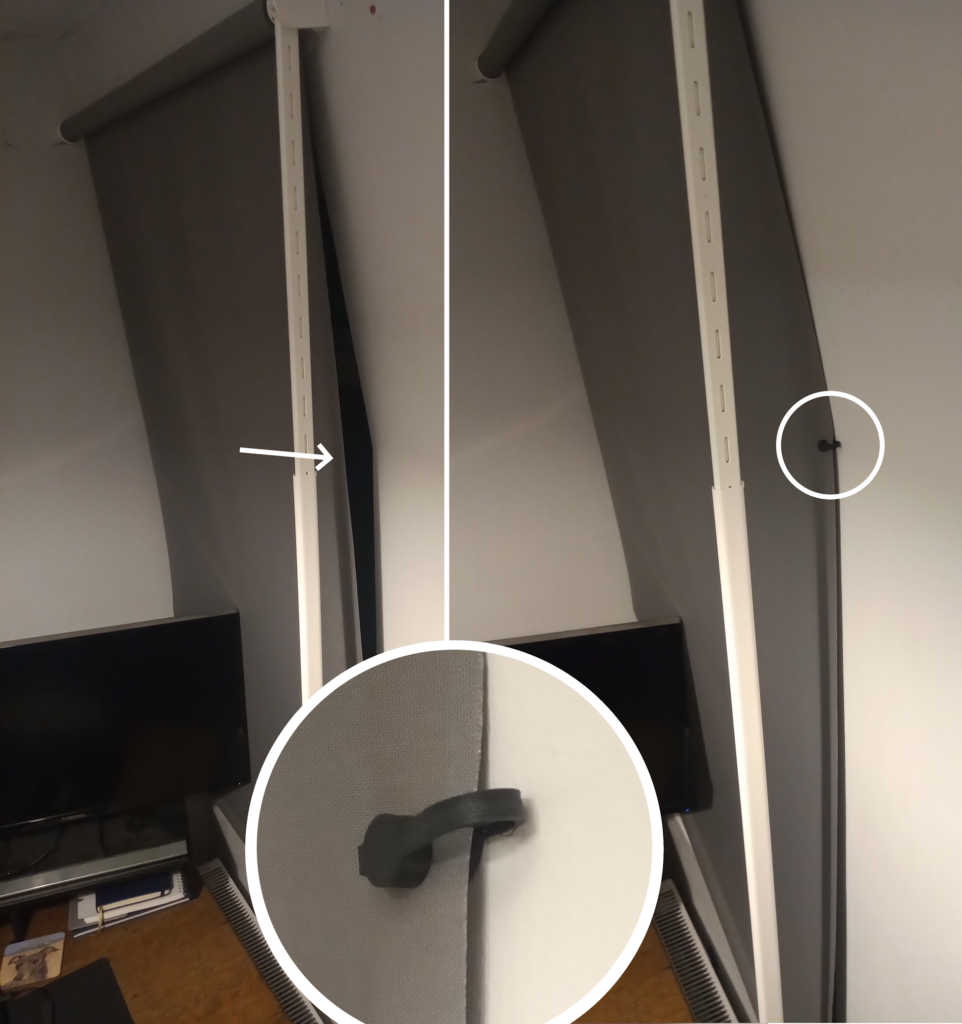

Due to the odd shape of the walls in our upper floor, the roller blinds over the window let in a lot of light. This project was to create a simple magnetic clip to retain a blind against a wall to prevent light leaking around the side.

The flexible TPU filament is perfect for this application and the total print time was circa 15mins.

the settings that were used:

- Nozzle temp = 230 oC

- Bed temp = OFF / 0 oC (keep the work area cool)

- Print speed = 20 mm/s

- Part cooling = low for first couple of layers, then high.

- Retraction = OFF (yes, you will get stringing, but a stringy print is better than a failed print)

- Your settings may vary depending on many factors.

Tips and Notes:

- Any retraction movements will cause the extruder gear to create teeth marks in the filament. These marks lead to greater amounts of friction within the Bowden tube and this has a higher chance of jamming.

- The material is soft, so ease off the pressure on the extruder idler.

- Some people note that the bed should be 30 oC, however, I think this warms the filament and makes it softer. That could be superstition.

- A legit Capricorn tube from Creality will help – the inner bore is greater precision with a smoother surface.

Best of luck!